Today I got the trailer in from the garage to continue evaluating the options to convert it into a proper transportation tool. Just too cold to do this in the garage at the moment: -4 C or 24.8 F.

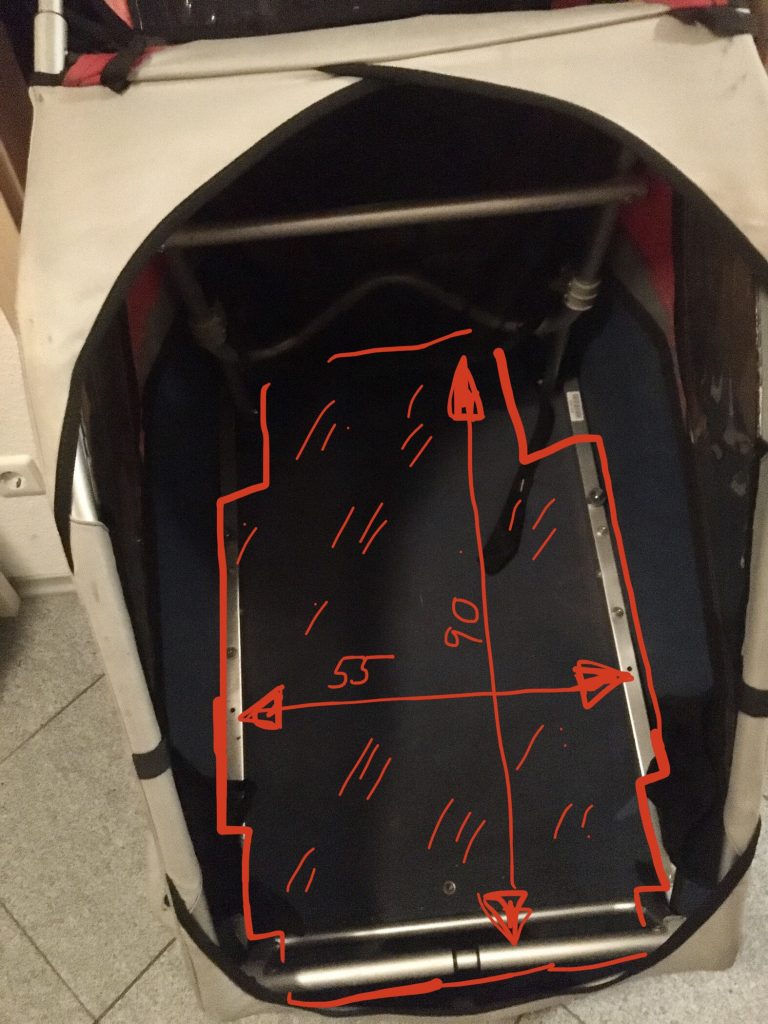

So I continued de-installing the kids seats to be able to measure the width and length required for a proper floor.

I will need to cut out some parts to adhere to the non-rectangle parts of the trailer as well as the space required when you fold it together.

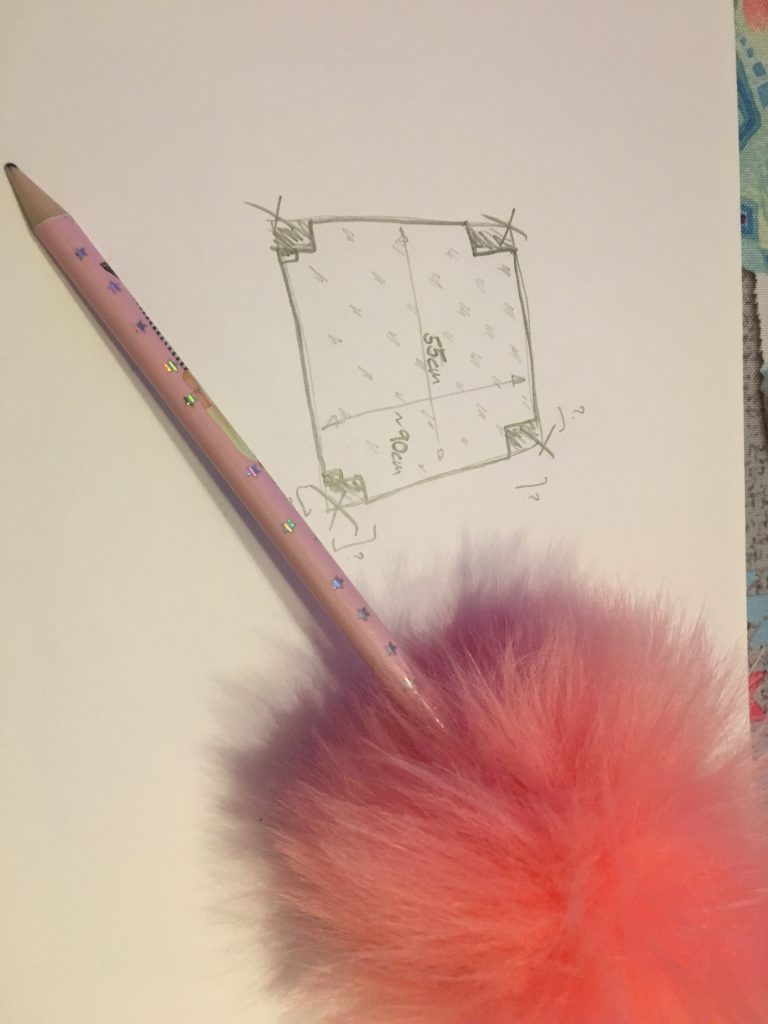

I am thinking of using an alloy floor (German: Riffelblech) and will now spend some time on planning.

Main thought is how to cut it to fit correctly. I have a metal saw but wonder how crooked it will be by hand. Hmm…

But by planning with this pen of my daughter nothing can go wrong 😂

5 thoughts on “PACKHORSE II”

Leave a Reply

You must be logged in to post a comment.

If its only the corners, that should work pretty well with a metal saw – otherwise I could help you cutting with equipment like this https://www.bosch-professional.com/de/de/products/gco-14-24-j-0601B37200

Oh – thank you!! That would be very helpful. I was wondering how to manage it. Having it pre-cut is also possible yet drives the price significantly! My next step this week is to prototype with a wooden version of the floor before I invest more money or cut it the wrong way. I have Thursday and Friday off so I’ll have another post up here with the results of the “prototyping activity” 😀

Do you have experience with alloy? Like how thick would you estimate the floor should be to carry two cases of water? I was also thinking it might be smart to opt for a lighter floor and give it strength by adding some support below. (Querstreben)

Did not work a lot with alloy. Supports below sounds like a good idea. Usually I would weld things like this together – but my equipment does not work for alloy. So I would recommend blind rivets for this.

Good idea💡 I think when allowed and reasonable again I have to plan a trip to your place for some building 😄 It looks like cutting the curves and small parts can be done with a jig saw and special blades as well. But I will likely need your support to cut long straight cuts into the alloy. I finished the prototype today and posted a new blog entry about it. Maybe you have some ideas on brackets to fasten luggage?